-

Ceyhan CapanogluI always add get lots of useful suggestions from Wangtai factory, they are professional, hardworking and careful.

Ceyhan CapanogluI always add get lots of useful suggestions from Wangtai factory, they are professional, hardworking and careful. -

RichardWantai's materials are very good, the packaging is also good, the delivery speed is fast, the main price is affordable, the quality of made in China is very good.

RichardWantai's materials are very good, the packaging is also good, the delivery speed is fast, the main price is affordable, the quality of made in China is very good.

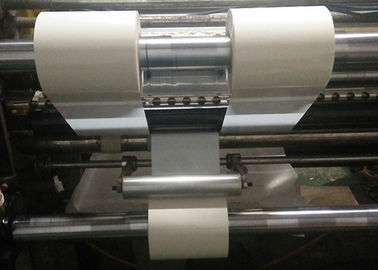

Non Toxic Matte PET Film Stable Performance With High Temperature Resistance

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | PET Protective Film | Type | Stretch Film |

|---|---|---|---|

| Usage | Packaging Film | Feature | Moisture Proof |

| Hardness | Soft | Processing Type | Multiple Extrusion |

| Highlight | matte polyester film,matte lamination film |

||

High-temperature resistance matte PET films

The matte PET Film can resist 150 degrees for half an hour. The surface does not reflect light. The degree of matte is 5 (0 when testing with water). It can be used for light diffusing Films, silicone products, PU, TPU. This series of products can be customized depending on your needs. We sincerely welcome you to become agent of our products. Wholesale and retail are both welcome.

Characteristics:

1. This product is Environmentally-friendly, non-toxic, odorless and benzene-free.Solvent is not used during the production, therefore harmless to the Environment and people

2. Stable performance with resistance to high temperature (150 degrees). We can produce product with surface that has tension and release force.

3. The production efficiency and the product quality can be largely improved when producing products with harsh temperature requirement.

4. Wide adaptability. It can be used for light diffusing Films, laminating, rubberizing and protective Films.

| Item | Unit | Index | Test method | |||||

| Thickness | µm | 55 | 80 | 105 | 120 | 195 | GB12802.2-2004 | |

| Deviation of thickness | % | ±2 | ±2 | ±3 | ±3 | ±4 | ||

| Tensile strength | MD | Mpa | ≥180 | ≥175 | ≥170 | ≥160 | ≥150 | GB12802.2-2004 |

| TD | ||||||||

| Elongation at break | MD | % | ≥100 | ≥100 | ≥100 | ≥100 | ≥100 | GB12802.2-2004 |

| TD | ||||||||

| (150℃,30min) | MD | % | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | GB12802.2-2004 |

| Heat shrinkage | TD | ≤0.6 | ≤0.6 | ≤0.6 | ≤0.6 | ≤0.6 | ||

| Haze | % | ≤1.0 | ≤1.5 | ≤2.0 | ≤2.6 | ≤4.0 | GB2410-80 | |

| Wetting tension | mN/m | ≥52 | GB/T 13541-1992 | |||||

| Electrical strength | V/µm | ≥100 | ≥95 | ≥90 | ≥80 | ≥66 | GB12802.2-2004 | |

| Volume resistivity | Ω.m | ≥1×1014 | GB12802.2-2004 | |||||

| Relative dielectric constant(50Hz) | 2.9~3.4 | GB12802.2-2004 | ||||||

| Dielectric loss tangent(50Hz) | ≤3×10-3 | GB12802.2-2004 | ||||||